Koryx Copper Announces Further Drill Assay Results Extending Consistent Mineralization at Depth and Laterally at the Haib Copper Project, Southern Namibia

Highlights

| • Completed a further 7 drill holes for 2,986m out of a planned 178 holes in Phase 2, 3 and 4. | |

|

• 15,349m of the 28,000m drill target for 2025 has been completed to date. | |

|

• Drill results extended mineralization into some areas previously modelled as waste. | |

| • HM75: | 927m @ 0.24% Cu (entire hole) |

| 14m @ 0.58% Cu (4 to 18 m) | |

| 60m @ 0.33% Cu (302 to 362m) | |

| 28m @ 0.35% Cu (422 to 450 m) | |

| 48m @ 0.34% Cu (820 to 868m) | |

| • HM77: | 98m @ 0.37% Cu (86 to 184m) |

| • HM88: | 56m @ 0.34% Cu (126 to 182m) |

| • HM72: | 52m @ 0.32% Cu (36 to 88m) |

| 10m @ 0.46% Cu (258 to 268m) | |

| 14m @ 0.91% Cu (558 to 572m) | |

| • HM89: | 100m @ 0.31% Cu (42 to 142m) |

| 58m @ 0.37% Cu (278 to 336m) | |

| • HM85: | 74m @ 0.31% Cu (80 to 154m) |

| 16m @ 0.33% Cu (192 to 208m) | |

| • 6 drill rigs currently active on site. A further 4 man-portable drill rigs are due to arrive in Namibia in September increasing total drill rig count on site to 10. | |

| • Ongoing ore sorting and coarse particle flotation trials indicate potential for significant pre-milling waste rejection and reduced processing costs. | |

| • Updated PEA, based on existing published MRE (dated October 23, 2024) and excluding all new drilling completed since then, to be published during September 2025, to be followed by an updated MRE and technical study (including all current drilling) during H2 2026. | |

VANCOUVER, British Columbia, Aug. 28, 2025 (GLOBE NEWSWIRE) -- Koryx Copper Inc. (“Koryx” or the "Company") (TSX-V: KRY) is pleased to announce assay results from seven drill holes (2,986m) received as part of the Phase 2, 3 and 4 drill program for its 2025 exploration and project development strategy, on the wholly-owned Haib Copper Project (“Haib” or the “Project”) in southern Namibia. Haib is an advanced-stage copper/molybdenum/gold project that is envisaged to produce a copper concentrate via a conventional crushing/milling/flotation metallurgical process, with the potential for additional copper production via heap leaching.

Heye Daun, Koryx Copper’s President and CEO commented: "We continue to be highly encouraged by the results of our ongoing drill program. Our strategy of drilling close spaced and deeper holes is paying dividends as we are seeing mineralization extending down dip and along strike into areas previously classified as waste. Also, the re-logging of historical drill core to Koryx’s standardized core logging procedures will allow us to develop a geo-metallurgical model that incorporates data collected across multiple generations of exploration drilling. Already, our geologists are better able to identify correlation between copper grades and geology, which allows us to better plan drill locations, as we seek to identify higher grade zones and de-risk the project. This increased drill density should assist in a much improved and tighter geological interpretation with the next mineral resource update. The potential improvement in mineral resources together with the conventional mill/float metallurgical flowsheet should further transform the Haib project into a robust, low risk, long life, world-class open pit copper development project with serious scale potential.”

Preliminary Economic Assessment Guidance

As part of its Mining License Application Process, the Company recently completed a Preliminary Economic Assessment (“PEA”) of the techno-economic feasibility of the Haib project and expects to publish the results during September 2025. This PEA is based on the Updated Mineral Resource dated October 23, 2024, and does not yet include any of the drilling or geological modelling work completed since then. It does however reflect the progress made by the new Koryx technical team with respect to the updated metallurgical testwork and process flowsheet development since the previous PEA, published December 15, 2021.

This updated PEA will reflect an improved, low risk process flowsheet utilizing mainly conventional milling & flotation, instead of the previously envisaged bacterial heap leaching, and it reflects all of the progress made with respect to metallurgical testwork, infrastructure trade-offs and de-risking and significant progress with respect to pre-concentration and sorting of mineralized material.

The objective of publishing this updated PEA, based off an outdated MRE, is to reset and reposition the Haib project as a large-scale, low risk, low cost, conventional milling & flotation project, instead of a small-scale, high risk bacterial heap leaching project. The objective also is to demonstrate techno-economic feasibility of this process route, using recent input assumptions and updated metallurgical test work. As the drilling, assaying and geological re-modelling of the updated Haib mineral resource is anticipated to still require at least 6-9 months, this September 2025 PEA will be based on the existing mineral resource, which excludes all of the recent drilling.

It is expected that completion of the current infill & expansion drill program, and subsequent geological modelling and mine planning will be completed during H1 2026. Following on from that, an updated Mineral Resource Estimate will be published late in H1 2026 and an updated, PFS-level technical study is planned to be completed thereafter, early during the 2nd half of 2026.

With the anticipated mineral resource and processing improvements to be completed by then, the next technical study has the potential to very significantly further improve the technical and economic results pertaining to the Haib copper project. This is what Koryx Copper is working towards.

Discussion of Drill Results

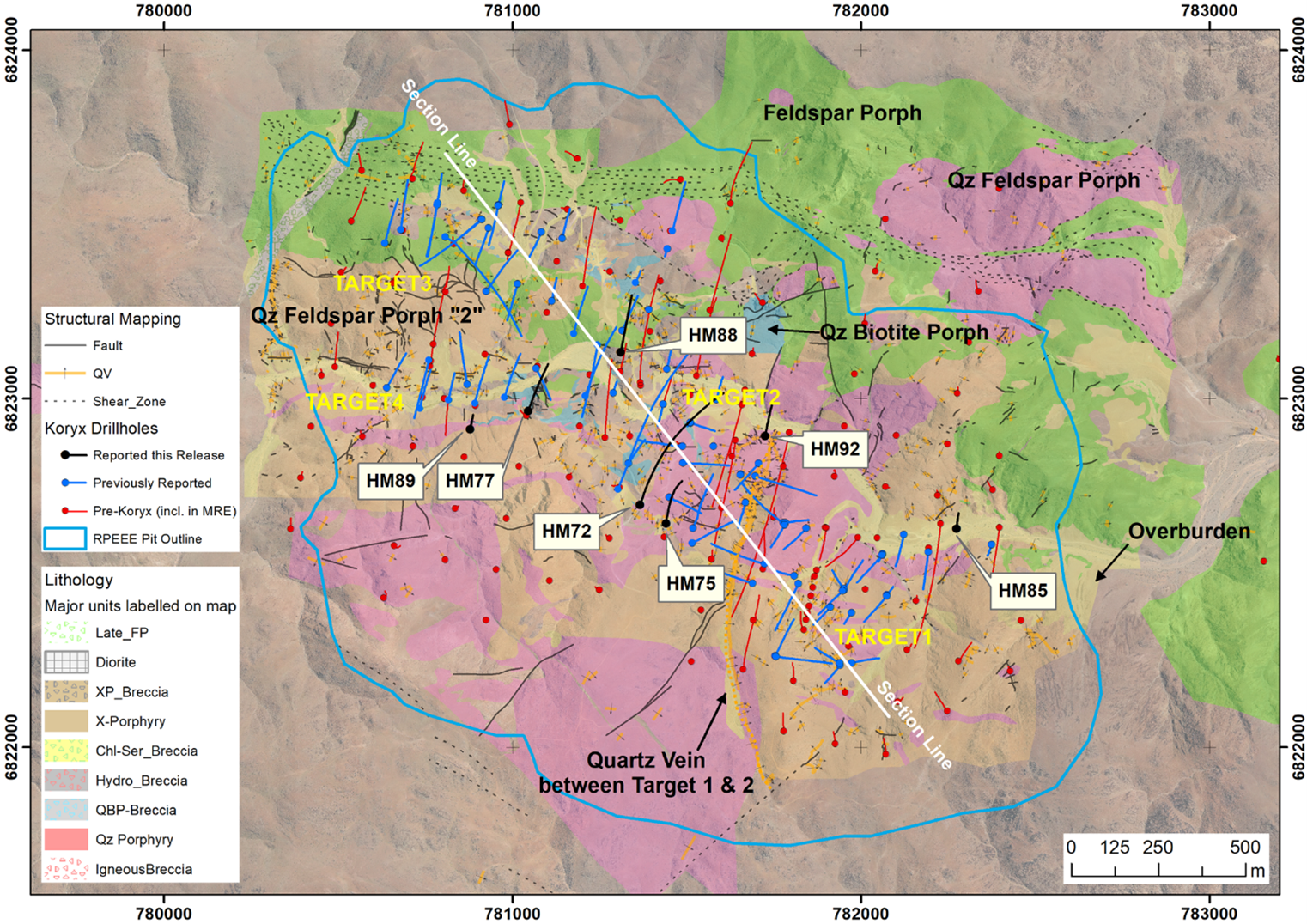

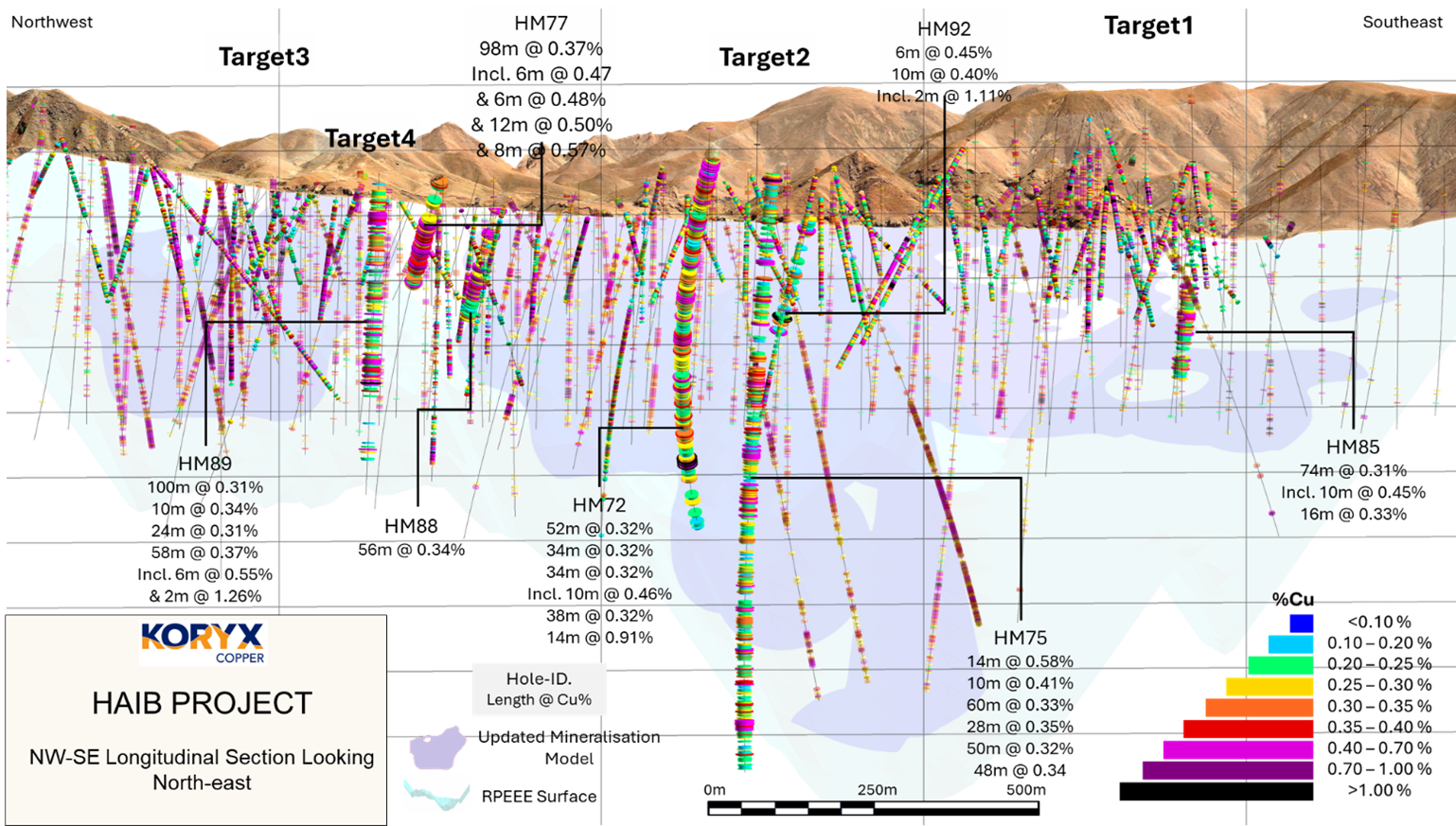

Target 1 Results

HM85 was drilled north of the Volstruis River, on the eastern side of Target 1. In this area, the river course is thought to follow an east–west-trending fault zone, and the hole was positioned to test the down-dip extension of mineralization from Target 1 across this potential structure. Mineralization coincides with a transition from fine-grained porphyritic granodiorite to a coarser-grained phase. From this point, mineralization extended approximately 20m deeper than currently modelled, with grades exceeding previous estimates. A second zone of higher-grade mineralization was intersected from 200m, averaging over 0.3% Cu and peaking at 0.6%. This zone has not been intersected by earlier drilling.

Target 2 Results

HM72 was drilled west of HM75 and approximately 80m east of HM73 (previously reported). Results are broadly comparable to HM73, with the full 695m length averaging more than 0.24% Cu. Numerous mineralised intersections are associated with strong molybdenum grades, reaching up to 0.56% Mo in one sample. Together with HM73 and HM75, these results are expected to contribute materially to both resource tonnage and grade increases. Notably, a 14m interval grading 0.91% Cu at a vertical depth of ~400m confirms the continuation of high-grade mineralization at depth in this area.

Figure 1: Plan view indicating the seven recent drill hole result locations

Figure 2. Long section looking northeast showing the seven reported drill hole intersection depths relative to the model for Cu mineralization. True widths/thickness of the mineralization are unknown.

Target 2 Results Continued

HM75 was drilled near the southwest contact of the central portion of Target 2, returning highly positive results in terms of potential tonnage and grade increases. Over its full 927m length, the hole averages more than 0.24% Cu. Copper grades to 350m downhole are broadly consistent with expectations; however, deeper intersections represent a significant resource addition relative to the current model where mineralization continued outside of the expected envelope of mineralization.

In addition, molybdenum is well developed from surface to approximately 870m, with grades up to 0.29% Mo.

HM92 was drilled on the northern margin of the central portion of Target 2 to close sample spacing and assess the potential for deeper mineralization. Results indicate an approximate 40m northward lateral extension of mineralization in this area. At depth, copper mineralization occurs more sporadically in narrow intersections, while molybdenum is virtually absent in these deeper zones.

Target 3 Results

HM88 was drilled in the transition zone between Targets 2, 3, and 4, positioned to test the east–west-trending fault zone mapped along the Volstruis River and previously identified by both Teck and RTZ. From surface to the interpreted northern contact of the fault (~68m downhole), Cu grades are low and Mo is largely absent.

Beyond this point, Cu grades improve significantly and show good correlation with the existing model. Mo remains very low until 434m downhole, where it increases markedly.

Target 4 Results

HM77 was drilled in the eastern part of Target 4 to close sample spacing. Results are broadly consistent with expectations, with a resource tonnage reduction near the top of the hole offset at depth by gains in both tonnage and grade relative to the current model.

HM88 was drilled in the southern part of Target 4 to test the high-grade mineralized zone previously identified by historical RTZ holes HB029 and HB067. Results correlate closely with the current model, confirming the presence of a significant mineralized zone initially defined only by historical data. Importantly, HM88 also provides the first detailed lithological, alteration, and structural information from this zone.

The true widths/thickness of the mineralization in the target results are unknown.

Molybdenum and Gold Mineralization

Assay results confirm ongoing molybdenum mineralization across all tested samples. Molybdenum grade is known to be not well correlated with Cu, but areas of higher-grade Mo are consistently seen throughout the system, and in these recent results HM72 produced 38m @ 0.037% Mo (324 to 362m). The additional Mo data is providing the framework to produce a dedicated Mo model for updating the by-product resource estimate in the next model iteration.

All samples are also being assayed for gold in addition to the multielement analysis, and background levels of approximately 0.025g/t of Au are found throughout the porphyry. Narrower intervals of up to 10m often contain 0.05g/t Au but, like Mo, are poorly correlated with the Cu grade. The expected substantial increase in the assay database will allow for better modelling and a gold estimation in the next mineral resource model update planned for H1 2026.

Table of Significant Intersections

| Hole# | Zone | From (m) | To (m) | Width (m)1 | Cu (%) | Mo (%) | Au (g/t) |

|

HM72 |

Entire Hole | 0 | 695 | 695 | 0.24 | 0.011 | 0.019 |

| Main | 16 | 28 | 12 | 0.31 | 0.006 | 0.022 | |

| Main | 36 | 88 | 52 | 0.32 | 0.007 | 0.028 | |

| Including | 36 | 40 | 4 | 0.52 | 0.005 | 0.043 | |

| Main | 116 | 150 | 34 | 0.32 | 0.009 | 0.019 | |

| Main | 246 | 280 | 34 | 0.32 | 0.011 | 0.017 | |

| Including | 258 | 268 | 10 | 0.46 | 0.009 | 0.019 | |

| Main | 324 | 362 | 38 | 0.32 | 0.037 | 0.023 | |

| Main | 424 | 430 | 6 | 0.43 | 0.011 | 0.022 | |

| Main | 476 | 482 | 6 | 0.32 | 0.024 | 0.019 | |

| Main | 492 | 498 | 6 | 0.32 | 0.016 | 0.018 | |

| Main | 510 | 524 | 14 | 0.30 | 0.025 | 0.020 | |

| Main | 558 | 572 | 14 | 0.91 | 0.003 | 0.091 | |

| Including | 560 | 566 | 6 | 1.13 | 0.004 | 0.153 | |

| Including | 570 | 572 | 2 | 1.11 | 0.002 | 0.051 | |

|

HM75 |

Entire Hole | 0 | 927 | 927 | 0.24 | 0.010 | 0.021 |

| Main | 4 | 18 | 14 | 0.58 | 0.006 | 0.027 | |

| Including | 8 | 12 | 4 | 1.00 | 0.003 | 0.030 | |

| Main | 136 | 142 | 6 | 0.51 | 0.006 | 0.048 | |

| Main | 190 | 200 | 10 | 0.41 | 0.007 | 0.025 | |

| Main | 230 | 236 | 6 | 0.40 | 0.012 | 0.033 | |

| Main | 282 | 292 | 10 | 0.31 | 0.011 | 0.027 | |

| Main | 302 | 362 | 60 | 0.33 | 0.014 | 0.022 | |

| Main | 396 | 404 | 8 | 0.31 | 0.014 | 0.022 | |

| Main | 422 | 450 | 28 | 0.35 | 0.018 | 0.031 | |

| Including | 428 | 432 | 4 | 0.54 | 0.020 | 0.051 | |

| Main | 482 | 532 | 50 | 0.32 | 0.019 | 0.023 | |

| Main | 566 | 572 | 6 | 0.32 | 0.002 | 0.027 | |

| Main | 634 | 640 | 6 | 0.36 | 0.001 | 0.022 | |

| Main | 672 | 678 | 6 | 0.42 | 0.001 | 0.022 | |

| Main | 688 | 704 | 16 | 0.30 | 0.018 | 0.030 | |

| Main | 714 | 722 | 8 | 0.31 | 0.004 | 0.023 | |

| Main | 736 | 750 | 14 | 0.33 | 0.012 | 0.031 | |

| Main | 766 | 774 | 8 | 0.31 | 0.020 | 0.031 | |

| Main | 786 | 792 | 6 | 0.46 | 0.010 | 0.043 | |

| Main | 820 | 868 | 48 | 0.34 | 0.008 | 0.033 | |

|

HM77 |

Entire Hole | 0 | 222 | 222 | 0.26 | 0.008 | 0.016 |

| Main | 4 | 12 | 8 | 0.33 | 0.004 | 0.029 | |

| Main | 86 | 184 | 98 | 0.37 | 0.008 | 0.020 | |

| Including | 86 | 92 | 6 | 0.47 | 0.003 | 0.017 | |

| Including | 100 | 106 | 6 | 0.48 | 0.008 | 0.024 | |

| Including | 134 | 146 | 12 | 0.50 | 0.009 | 0.032 | |

| Including | 166 | 174 | 8 | 0.57 | 0.014 | 0.014 | |

|

HM85 |

Entire Hole | 0 | 223 | 223 | 0.22 | 0.003 | 0.032 |

| Main | 80 | 154 | 74 | 0.31 | 0.004 | 0.053 | |

| Including | 120 | 130 | 10 | 0.45 | 0.002 | 0.078 | |

| Including | 150 | 154 | 4 | 0.49 | 0.024 | 0.052 | |

| Main | 192 | 208 | 16 | 0.33 | 0.002 | 0.033 | |

|

HM88 |

Entire Hole | 0 | 220 | 220 | 0.19 | 0.002 | 0.019 |

| Main | 68 | 74 | 6 | 0.43 | 0.000 | 0.036 | |

| Main | 126 | 182 | 56 | 0.34 | 0.002 | 0.024 | |

|

HM89 |

Entire Hole | 0 | 495 | 495 | 0.22 | 0.008 | 0.027 |

| Main | 42 | 142 | 100 | 0.31 | 0.005 | 0.031 | |

| Including | 62 | 70 | 8 | 0.62 | 0.023 | 0.051 | |

| Including | 74 | 80 | 6 | 0.54 | 0.002 | 0.041 | |

| Main | 188 | 198 | 10 | 0.34 | 0.002 | 0.044 | |

| Main | 226 | 250 | 24 | 0.31 | 0.011 | 0.030 | |

| Main | 278 | 336 | 58 | 0.37 | 0.011 | 0.037 | |

| Including | 288 | 294 | 6 | 0.55 | 0.004 | 0.039 | |

| Including | 322 | 324 | 2 | 1.26 | 0.032 | 0.060 | |

|

HM92 |

Entire Hole | 0 | 205 | 205 | 0.17 | 0.001 | 0.016 |

| Main | 20 | 26 | 6 | 0.45 | 0.011 | 0.025 | |

| Main | 96 | 100 | 4 | 0.33 | 0.001 | 0.025 | |

| Main | 174 | 184 | 10 | 0.40 | 0.002 | 0.021 | |

| Including | 174 | 176 | 2 | 1.11 | 0.003 | 0.037 |

- Widths are interval widths and not true widths, as the true thickness/widths of the mineralization are unknown. The reported intervals are calculated using the following parameters:

- Only Cu (%) was used to determine the intervals.

- The target composite grade is ≥0.30% Cu.

- Composites start and end with samples ≥0.30% Cu.

- Grades between 0.20% and 0.30% are included in interval but generally constitute <40% of the interval.

- Consecutive samples between 0.20% and 0.30% should be fewer than 5 samples (10m).

- Grades below 0.20% are included but generally constitute <20% of the interval.

- Consecutive grades <0.2% should be fewer than 2 samples (4m).

Surface Mapping and Updated Logging Database

The detailed re-logging of historical core has been completed. The re-logging includes previous Koryx drill core and all available core from drilling carried out on the project since the late 1990’s, which can now be integrated with the more detailed logging implemented under the guidance of Dr. Warren Pratt since late 2024. The new logging data will be combined with the ongoing surface mapping to create new geological, alteration and structural models. Preliminary interpretations using the new geological and structural logging indicate better correlation with copper grade. Additionally, for the first time a molybdenum model is definable based on systematic assays and structural logging in particular. The three-dimensional models will inform the targeting of higher-grade copper and molybdenum mineralization, assist in better constraining the copper and molybdenum grade models and the updating of the resource estimate planned for H1 2026.

Drilling Progress Discussion

Drilling has continued with the four track-mounted rigs and two additional man-portable drill rigs have arrived on site and began drilling in August. The new drill rigs began production over the last week, and these new rigs are expected to significantly increase the monthly meter rate towards the 28,000m drill program planned by the end of the year.

Four more man-portable rigs are due to arrive in Namibia in September before being commissioned and deployed to the Project to begin drilling in October. These additional rigs will build capacity towards ramping up drilling production towards the 55,000m drilling program expected to be completed in H2 2026.

Metallurgical Test Work Update

Crushing, milling and flotation tests have continued using drill core and composite samples compiled from the core shed on site. Copper recovery results have been consistent with earlier press releases, and recovery of molybdenum from copper into a separate marketable concentrate has been demonstrated to be achievable.

Over the last two months, bulk and particle mineralized material sorting as well as coarse particle flotation (“CPF”) tests have commenced, with the objective of rejecting barren waste rock minerals containing little or no copper from flotation feed. This reduces processing costs per unit of copper produced.

Coarse particle flotation tests have successfully generated a discardable >150µm tailings stream amounting to about 15% of bulk conventional flotation feed. Ore sorting tests are not as far advanced yet but simulations have been carried out based on initial confirmation that sensors of different types can identify chalcopyrite in Haib mineralized material samples and evaluation of the drill core databases. These simulations indicate that possibly 15 to 20% of the run of mine crusher feed could be rejected ahead of milling, without significant losses of copper.

More detail about these tests and the results will be included in the planned PEA press release which is due to be issued within the next few weeks, relating to the Preliminary Economic Analysis of the Haib project.

Mine Infrastructure Update

Studies to advance the non-process plant infrastructure specific to the terrain environment at Haib have been significantly progressed by the engineering team. The mine site area was assessed to locate the preferred plant location and then to optimize the main waste rock dumps and tailings facilities in relation to this position. Trade-off studies were then able to identify near optimal locations for potential office and housing locations as well as access and internal road solutions.

Power and water supply studies have identified feasible alternatives to supply the conceptual mine design for the range of alternative plant throughput options considered. Water consumption in the range of 20M m3pa and approximately 150 MW of maximum power demand including milling and flotation have been presented to the Namibian parastatal water and power utilities, NamWater and NamPower, respectively. Both NamWater and NamPower have begun critically assessing the grid and network capacities in southern Namibia to provide solutions in partnership with the Project and have begun advanced discussions with the Project engineers.

Trade off studies during the PEA phase have provided the basis for recommendations for further study. The Knight Piésold engineering team has begun early work to produce a more detailed design recommendation in the upcoming PFS phase of the Project study.

Quality Control

All drill core was logged, photographed, and cut in half with a diamond saw. Half of the core was bagged and sent to ALS Laboratories Ltd. in Johannesburg, South Africa for analysis (SANAS Accredited Testing Laboratory, No. T0387) and ActLabs in Canada, while the other half was quartered with one quarter archived and stored on site for verification and reference purposes while the other quarter will be used for metallurgical test work. 33 elements are analyzed by Induced Coupled Plasma (ICP) utilizing a 4-acid digestion and gold is assayed for using a 30g fire assay method. Duplicate samples, blanks, and certified standards are included with every batch and are actively used to ensure proper quality assurance and quality control (“QA/QC”) The QA/QC frequency is 1 in 20 for each of blanks, duplicates and standards.

Qualified Person

Mr. Dean Richards Pr.Sci.Nat., MGSSA – BSc. (Hons) Geology is the Qualified Person for the Haib Copper Project and has reviewed and approved the scientific and technical information in this news release and is a registered Professional Natural Scientist with the South African Council for Natural Scientific Professions (Pr. Sci. Nat. No. 400190/08). Mr. Richards is independent of the Company and its mineral properties and is a Qualified Person for the purposes of National Instrument 43-101.

About Koryx Copper Inc.

Koryx Copper Inc. is a Canadian copper development Company focused on advancing the 100% owned Haib Copper Project in Namibia whilst also advancing its portfolio of copper exploration licenses in Zambia. Haib is a large, advanced (PEA-stage) copper/molybdenum porphyry deposit in southern Namibia with a long history of exploration and project development by multiple operators. More than 90,000m of drilling has been conducted at Haib since the 1970’s with significant exploration programs led by companies including Falconbridge (1964), Rio Tinto (1975) and Teck (2014). Extensive metallurgical testing and various technical studies have also been completed at Haib to date.

Additional studies are underway aiming to demonstrate Haib as a future long-life, low-cost, low-risk open pit, sulphide flotation copper project with the potential for additional copper production from heap leaching. Haib has a current mineral resource of 414Mt @ 0.35% Cu for 1,459Mt of contained copper in the Indicated category and 345Mt @ 0.33% Cu for 1136Mt of contained copper in the Inferred category (0.25% Cu cut-off).

Mineralization at Haib is typical of a porphyry copper deposit and it is one of only a few examples of a Paleoproterozoic porphyry copper deposit in the world and one of only two in southern Africa (both in Namibia). Due to its age, the deposit has been subjected to multiple metamorphic and deformation events but still retains many of the classic mineralization and alteration features typical of these deposits. The mineralization is dominantly chalcopyrite with minor bornite and chalcocite present and only minor secondary copper minerals at surface due to the arid environment.

Further details of the Haib Copper Project are available in the corresponding technical report titled, "NI 43-101 Technical Report – August 2024 Mineral Resource Estimate for the Haib Copper Project, Namibia" dated effective August 31, 2024 (the "Technical Report"). The Technical Report and other information is available on the Company's website at https://koryxcopper.com and under the Company's profile on SEDAR+ at www.sedarplus.ca.

ON BEHALF OF THE BOARD OF DIRECTORS

"Heye Daun"

President, CEO and Director

Additional information is also available by contacting the Company:

Julia Becker

Corporate Communications

jbecker@koryxcopper.com

+1-604-785-0850

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward-Looking Information

This press release contains "forward-looking information" within the meaning of applicable Canadian securities legislation. Forward-looking information includes, without limitation, statements regarding the use of proceeds from the Company's recently completed financings and the future or prospects of the Company. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect ", "is expected ", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved". Forward-looking statements are necessarily based upon a number of assumptions that, while considered reasonable by management, are inherently subject to business, market, and economic risks, uncertainties, and contingencies that may cause actual results, performance, or achievements to be materially different from those expressed or implied by forward-looking statements. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, other factors may cause results not to be as anticipated, estimated, or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking information. Other factors which could materially affect such forward-looking information are described in the risk factors in the Company's most recent annual management discussion and analysis. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/2d680591-d489-4c92-8bb8-b1164200fb52

https://www.globenewswire.com/NewsRoom/AttachmentNg/a6d72ef7-5410-4295-9cc8-9fa2ad9ea210

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.